At our company, we understand the importance of staying up-to-date with the latest trends and technologies in the indoor playground industry. As the demand for innovative and engaging kids indoor playground solutions continues to grow, we prioritize comprehensive training sessions for our employees.

At Huaxia Playground, our female employees are essential to our success, contributing creativity, dedication, and expertise across all aspects of our operations. Their hard work shines through in every piece of children's indoor playground equipment we produce, ensuring kids enjoy safe, engaging pla

Clients from Mexico visit our factory October 2017!

The IAAPA Expo, one of the most anticipated events in the amusement and attractions industry, is just around the corner. This global gathering of professionals is set to feature groundbreaking innovations, inspiring ideas, and exciting networking opportunities. Among the prominent exhibitors this ye

Dear Friends,I am excited to invite you to the IAAPA Expo Orlando 2024, where we will be showcasing our latest advancements in indoor children's playground equipment and outdoor non-powered amusement products. With over 25 years of expertise in manufacturing and sales, our company focuses on the des

The company extends warm holiday wishes to all employees, hoping for good health and a joyful work experience for everyone.

In this sunny and refreshing autumn season, all the employees of Huaxia Amusement Co., Ltd. embarked on a unique team-building activity - a trip to Daluo Mountain in Wenzhou with their yearning for nature and enthusiasm for the team. Daluo Mountain, a place of beautiful mountains and rivers known as

Vasia recently took part in the TAAPE Trade Show in Thailand, presenting our cutting-edge products and innovations to a broad spectrum of potential clients and industry experts. The event provided an excellent platform for us to feature our diverse range of premium indoor and outdoor playground equi

The success of HuaXia Amusement Co., Ltd. at the Vietnam Theme Park Exhibition underscores the company's dedication to excellence and its strong presence in the amusement park and children's playground equipment sector. By showcasing their latest innovations, the company not only demonstrated their

SGS, a renowned authority in quality assurance, has bestowed upon our company the prestigious QTL accreditation for our laboratory facilities. This recognition signifies that our testing procedures meet the rigorous standards set by SGS, encompassing everything from the testing environment and equip

| Availability: | |

|---|---|

| Quantity: | |

Tuv Certificates Children Ninja Warrior | |

Measurements (mm) | 2*3M for one project. Can be customized according to the layout |

Target age | 8-16 years |

Certificate | ISO14001,CE, ISO9001, GS, ASTM, EN1176 |

Obstacle |

Bracelet, foot ring, suspension bridge, monkey mountain climb, sponge bag, wall climb, hanging ladder, A-frame single pole. |

Material | Aluminum alloy, PVC leather, foam, sponge, LLDPE, Wood, etc |

| Production time | 15-28 days |

Installation | Provide detailed CAD instructions or skilled installation team. |

Payment | Usually by T/T. L/C or other payment also acceptable. |

Capacity | Usually one people in one game. |

Apply to | Trampoline park, schools, gyms, exercise center, shopping malls, etc. |

Packing | Standard export packaging includes bubble wrap and PP film for plastic components, while iron parts are secured with cotton and PP film to ensure safe and secure transportation. |

Warranty Period | 1 year |

Remark | Regularly inspect the screws and fasteners to ensure the structure remains secure. Always ensure children are supervised by an adult during play. Avoid using sharp objects or corrosive substances around the equipment. |

The TÜV certification for Children’s Ninja Warrior equipment ensures that the product meets rigorous safety, quality, and environmental standards. TÜV, a globally recognized testing and certification body, evaluates the equipment’s design, materials, and construction to confirm they adhere to international safety guidelines. This certification guarantees that the Ninja Warrior equipment is built with durable, non-toxic materials, offering a safe environment for children to engage in physical challenges. The TÜV seal of approval assures parents and operators that the equipment is both reliable and compliant with the highest standards, promoting safe, active play while reducing the risk of injury.

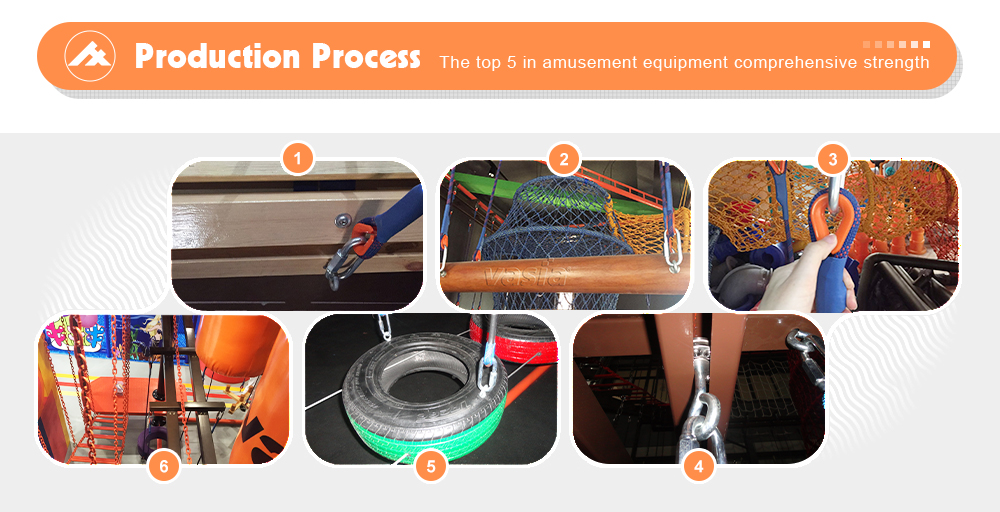

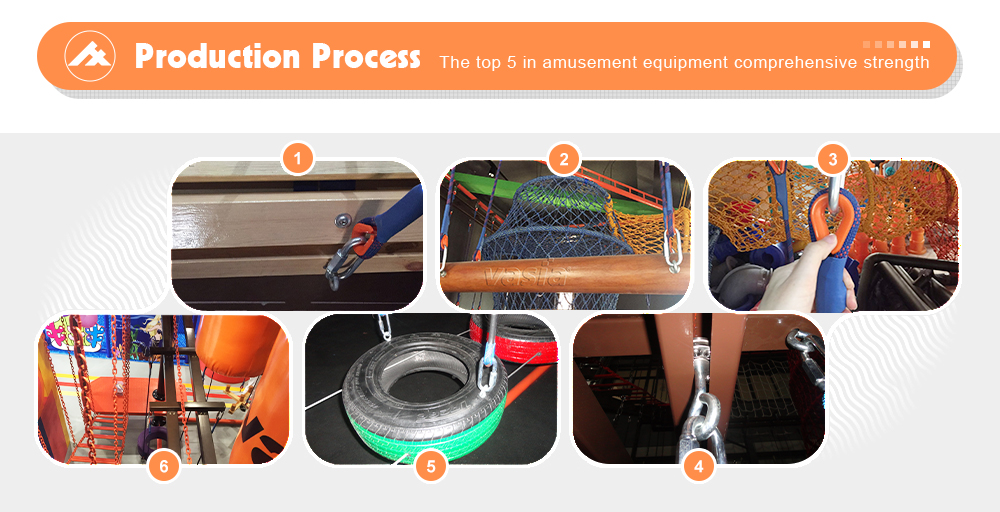

Raw Material: Steel or iron is inspected and prepared.

Cutting: The material is cut to precise dimensions.

Welding: Pieces are welded together for strength.

Polishing: Surfaces are smoothed and refined.

Shot Blasting: The metal is cleaned and prepped for coating.

Filling Sand Holes: Any imperfections are repaired.

Powder Coating: A durable, protective coating is applied.

Assembly: The parts are assembled into the final structure.

Packaging: Finished metal parts are carefully packed for shipment.

Raw Material: Wood is selected and inspected.

Cutting: The wood is cut to the required size.

Shaping: The wood is molded into desired shapes.

Soft Wrapping: Foam and upholstery are applied for safety and comfort.

Packaging: Finished products are securely packaged for delivery.

Raw Material: High-quality plastic (LLDPE) is chosen.

Color Mixing: The plastic is mixed with colors.

Rotational Molding: The plastic is heated and molded into shape.

Deburring: Excess material and rough edges are trimmed.

Assembly: The molded parts are assembled into the final product.

Packaging: Finished plastic parts are packed for transport.

These streamlined production processes ensure the creation of durable, safe, and high-quality ninja warrior.

The difficulty level of the entire course can be easily adjusted.

Each training area is equipped with starting and ending platforms.

Safety mats are used to secure additional platforms between obstacles.

The course includes a safety floor, which can be a foam cushion, inflatable mat, or foam pit.

A steel and soft mesh safety fence surrounds the course for added protection.

Optional additions include a timer and a display screen to show participants' results.

Vasia's mission is centered on fostering the healthy and happy growth of children. The company prioritizes children's well-being in the design of its products, which are strictly aligned with international playground safety standards. Vasia utilizes ASTM1487 (public playground equipment) and European EN1176 standards during production. Each ninja warrior undergoes rigorous testing before it is put into production to ensure it meets safety and quality criteria. Their quality management system is focused not only on maintaining high production standards but also on using advanced testing equipment to ensure every product complies with safety regulations and delivers optimal performance.

Tuv Certificates Children Ninja Warrior | |

Measurements (mm) | 2*3M for one project. Can be customized according to the layout |

Target age | 8-16 years |

Certificate | ISO14001,CE, ISO9001, GS, ASTM, EN1176 |

Obstacle |

Bracelet, foot ring, suspension bridge, monkey mountain climb, sponge bag, wall climb, hanging ladder, A-frame single pole. |

Material | Aluminum alloy, PVC leather, foam, sponge, LLDPE, Wood, etc |

| Production time | 15-28 days |

Installation | Provide detailed CAD instructions or skilled installation team. |

Payment | Usually by T/T. L/C or other payment also acceptable. |

Capacity | Usually one people in one game. |

Apply to | Trampoline park, schools, gyms, exercise center, shopping malls, etc. |

Packing | Standard export packaging includes bubble wrap and PP film for plastic components, while iron parts are secured with cotton and PP film to ensure safe and secure transportation. |

Warranty Period | 1 year |

Remark | Regularly inspect the screws and fasteners to ensure the structure remains secure. Always ensure children are supervised by an adult during play. Avoid using sharp objects or corrosive substances around the equipment. |

The TÜV certification for Children’s Ninja Warrior equipment ensures that the product meets rigorous safety, quality, and environmental standards. TÜV, a globally recognized testing and certification body, evaluates the equipment’s design, materials, and construction to confirm they adhere to international safety guidelines. This certification guarantees that the Ninja Warrior equipment is built with durable, non-toxic materials, offering a safe environment for children to engage in physical challenges. The TÜV seal of approval assures parents and operators that the equipment is both reliable and compliant with the highest standards, promoting safe, active play while reducing the risk of injury.

Raw Material: Steel or iron is inspected and prepared.

Cutting: The material is cut to precise dimensions.

Welding: Pieces are welded together for strength.

Polishing: Surfaces are smoothed and refined.

Shot Blasting: The metal is cleaned and prepped for coating.

Filling Sand Holes: Any imperfections are repaired.

Powder Coating: A durable, protective coating is applied.

Assembly: The parts are assembled into the final structure.

Packaging: Finished metal parts are carefully packed for shipment.

Raw Material: Wood is selected and inspected.

Cutting: The wood is cut to the required size.

Shaping: The wood is molded into desired shapes.

Soft Wrapping: Foam and upholstery are applied for safety and comfort.

Packaging: Finished products are securely packaged for delivery.

Raw Material: High-quality plastic (LLDPE) is chosen.

Color Mixing: The plastic is mixed with colors.

Rotational Molding: The plastic is heated and molded into shape.

Deburring: Excess material and rough edges are trimmed.

Assembly: The molded parts are assembled into the final product.

Packaging: Finished plastic parts are packed for transport.

These streamlined production processes ensure the creation of durable, safe, and high-quality ninja warrior.

The difficulty level of the entire course can be easily adjusted.

Each training area is equipped with starting and ending platforms.

Safety mats are used to secure additional platforms between obstacles.

The course includes a safety floor, which can be a foam cushion, inflatable mat, or foam pit.

A steel and soft mesh safety fence surrounds the course for added protection.

Optional additions include a timer and a display screen to show participants' results.

Vasia's mission is centered on fostering the healthy and happy growth of children. The company prioritizes children's well-being in the design of its products, which are strictly aligned with international playground safety standards. Vasia utilizes ASTM1487 (public playground equipment) and European EN1176 standards during production. Each ninja warrior undergoes rigorous testing before it is put into production to ensure it meets safety and quality criteria. Their quality management system is focused not only on maintaining high production standards but also on using advanced testing equipment to ensure every product complies with safety regulations and delivers optimal performance.